Хатогии формати почтаи электронӣ

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Ахбор

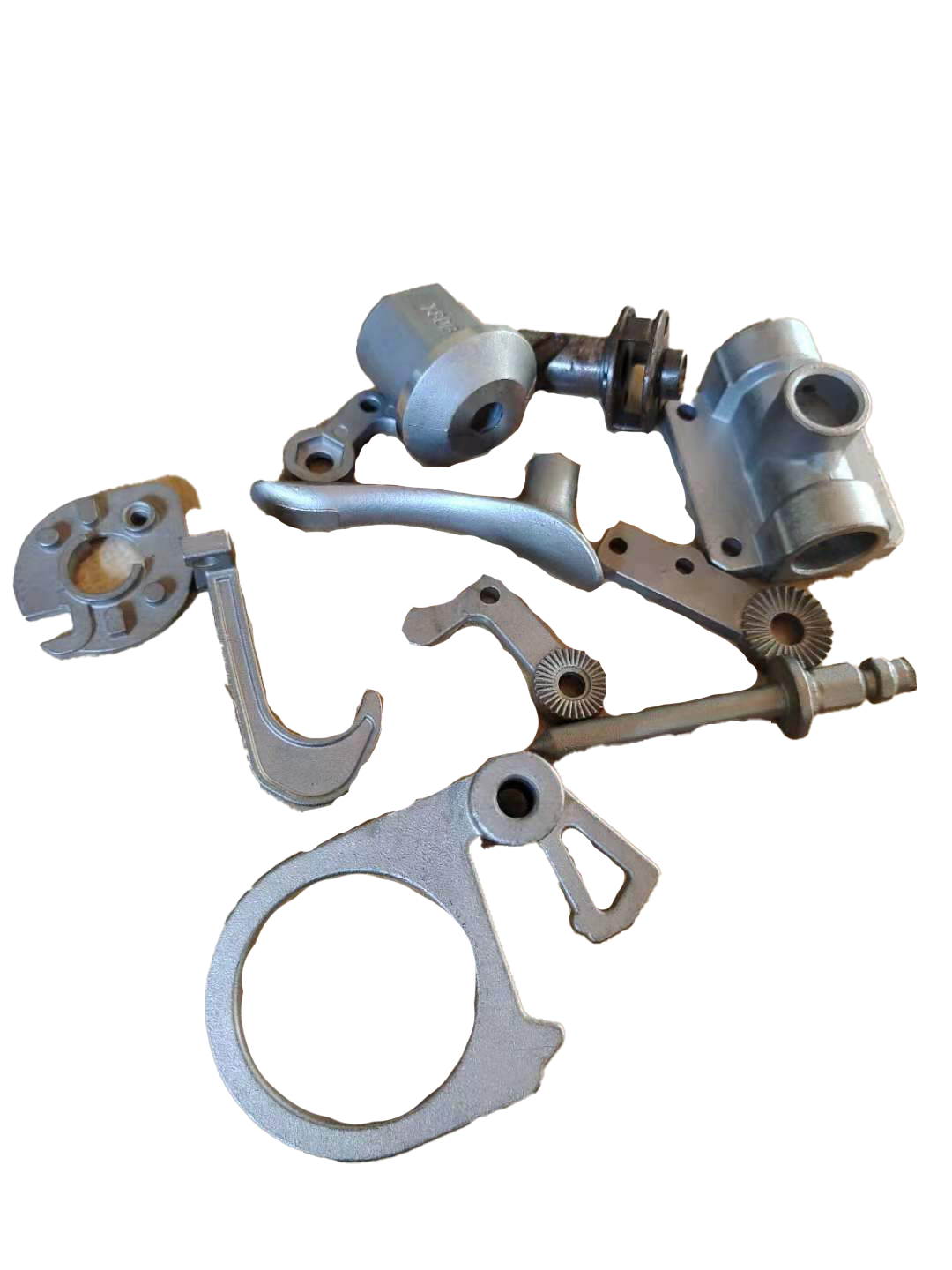

Why Is the Fourth Axis of the Machining Center So Popular

With the development of CNC technology, multi-axis CNC machining centers are being used more and more widely.

As the foundation of modern machinery manufacturing technology, CNC machining technology has brought significant changes to the machinery manufacturing process. Compared with traditional machining technology, modern CNC machining technology is significantly different in many aspects, such as machining technology, machining process control, and machining equipment and process equipment. The CNC machine tools we are familiar with have three linear coordinate axes, XYZ, and multi-axis refer to at least the fourth axis on a machine tool. It can be said that the emergence of multi-axis machining technology has driven the development of the machine tool industry.

Generally speaking, multi-axis CNC machining refers to CNC machining with more than 4 axes, and the representative one is 5-axis CNC machining. Multi-axis CNC machining can control the linkage of more than 4 coordinate axes at the same time, and combine functions such as CNC milling, CNC boring, and CNC drilling. It can effectively avoid the positioning error caused by multiple installations, shorten the production cycle and improve the processing accuracy. With the rapid development of mold manufacturing technology, higher requirements are placed on the processing capacity and processing efficiency of the machining center, so the multi-axis CNC machining technology has achieved unprecedented development.

Features of multi-axis machining

Reduce datum conversion and improve machining accuracy.

The process integration of multi-axis CNC machining not only improves the effectiveness of the process but also makes it easier to ensure machining accuracy because the parts only need to be clamped once during the entire machining process.

Reduce the number of fixtures and floor space.

Although the price of a single piece of equipment in a multi-axis CNC machining center is higher, due to the shortening of the process chain and the reduction in the number of equipment, the number of fixtures, workshop floor space, and equipment maintenance costs are also reduced.

Shorten the production process chain and simplify production management.

The complete machining of the multi-axis CNC machine greatly shortens the production process chain, and because only one job is assigned to the machining task, it not only simplifies production management and planning and scheduling but also significantly improves transparency. The more complex the workpiece, the more obvious its advantages over traditional production methods with decentralized processes. At the same time, due to the shortening of the production process chain, the number of products in the process will inevitably decrease, which can simplify production management, thereby reducing the cost of production operation and management.

Shorten the development cycle of new products.

For enterprises in aerospace, automobile and other fields, some new product parts and forming molds have complex shapes and high precision requirements. Therefore, multi-axis CNC machining centers with high flexibility, high precision, high integration and complete processing capabilities can well solve the precision and cycle problems of complex parts processing in the process of new product development, greatly shorten the development cycle and improve the success rate of new products.

Advantages of multi-axis machining

The multi-axis CNC machining center has the characteristics of high efficiency and high precision, and the workpiece can complete the processing of 5 surfaces after one clamping. If equipped with a high-end CNC system with a 5-axis linkage, it can also perform high-precision machining of complex spatial curved surfaces, which is very suitable for forming molds for workpieces such as auto parts and aircraft structural parts.

Its biggest advantage is that it makes the processing of the original complex parts much easier, shortens the processing cycle, and improves the surface processing quality. The improvement of product quality requires higher product performance. If it is processed by a double-turntable five-axis linkage machine tool, due to the special optical effect requirements of the headlight mold, many small curved surfaces used for reflection have very high processing accuracy and smoothness indicators. Requirements, especially the finish, almost require a mirror finish.

Using high-speed cutting technology equipment and a five-axis linkage machine tool to cut the mirror surface effect with a ball milling cutter becomes very easy, and it is almost impossible to achieve the relatively backward processing technology in the past. Using the five-axis linkage machine tool to process the mold can quickly complete the mold processing, fast delivery, better ensure the processing quality of the mold, make the mold processing easier, and make the mold modification easier.

In traditional mold processing, vertical machining centers are generally used to complete the milling of workpieces. With the continuous development of mold manufacturing technology, some weaknesses of the vertical machining center itself are becoming more and more obvious. Modern mold processing generally uses ball-end milling cutters. The benefits of ball-end milling cutters in mold processing are very obvious, but if a vertical machining center is used, the linear velocity of the bottom surface is zero, so the finish of the bottom surface is very poor. , If the four- and five-axis linkage machine tool processing technology is used to process the mold, the above shortcomings can be overcome.